Have you ever imagined wearing clothes that change according to the weather or the activity being performed? How about the possibility of producing adaptable stents enabling less invasive surgery? Believe me, this reality is getting closer every day with the evolution of printing with 4D technology. If you want to look forward to a bright future and learn how 4D printing will revolutionize the world, read on.

More than 30 years have passed since the invention of the 3D printer. During this time, there have been great advancements in this technology, ranging from gigantic and expensive machines to desktop printers, we even have 3D printers that can print in metal now! And it’s not just simple objects either, we’re starting to print extremely complex objects, like food, medicine and organs.

But when it comes to technology, time certainly doesn’t stand still and it’s time to move forward and go one beyond 3D. In truth, 4D printing wasn’t discovered recently, researchers and scientists have been working on developing this technology for a while now.

According to Paulo Abner Mesquita, who is the systems analyst at Atlantico, it’s still too early to say whether this is just a simple one-step evolution of the 3D printing process, or if in fact, 4D printing could have an ever larger effect than additive manufacturing has had over the last 30 years, which has indeed been world-changing. “As an example, in the near future 4D printing could allow a prosthesis or piece of clothing to adapt to changes in the human body, reducing the need for replacement.” explains Abner.

Leading this research is: Massachusetts Institute of Technology (MIT), Autodesk and Stratasys.

What is 4D printing?

To help better understand what 4D printing is, Abner gives the movie “Transformers” as an example, in which robots are transformed into different vehicles (cars, buses, trucks, planes, etc.). “Well, that’s exactly what happens in 4D printing, the transformation of the geometric structure of an object from one shape to another. This structural change happens due to the reaction that occurs between the material used to print the object and a reagent, such as: water, light, temperature, or any stimulus coming from the environment.”, he explains.

This concept has generated a lot of research that combines the design of self-assembling objects and the so-called smart-materials, which are materials that have the characteristic of changing their structure according to the environment in which they are immersed. This new technology could have a major impact on several sectors, such as construction, manufacturing, industrial assembly, fashion and health.

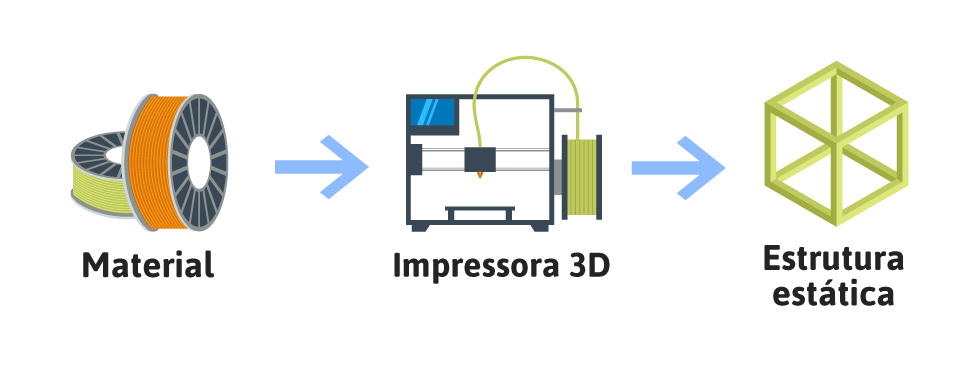

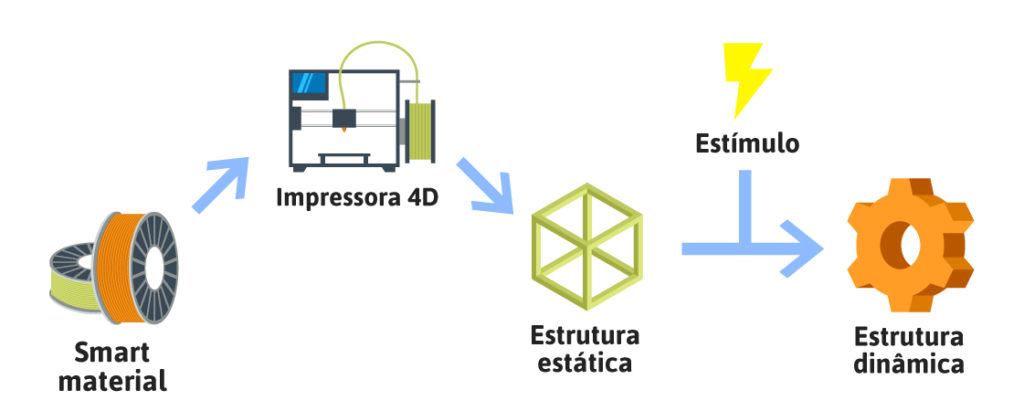

Understanding the difference between 3D and 4D printing

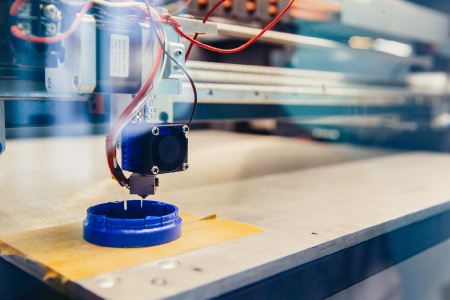

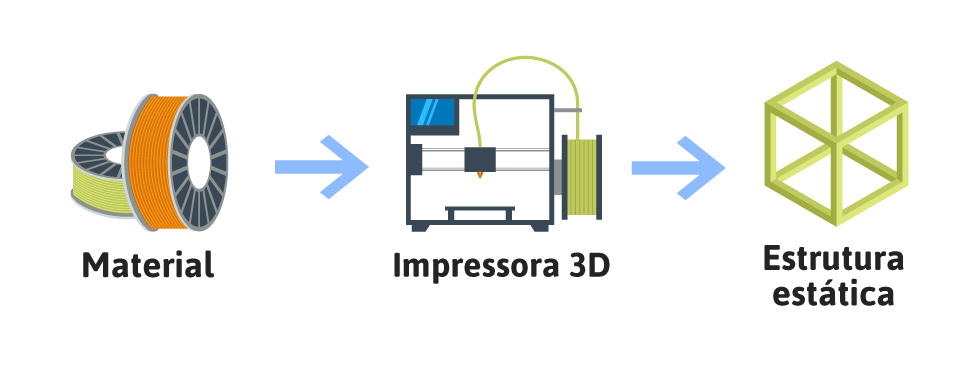

The difference between the 3D and 4D printing process is in the materials used and the exposure of the object to a given environment. To help understand further, let’s go deeper into the process: 3D printing prints objects from 3 dimensional sketches using powder, polymers, plastic filaments or resins. This is done through one of several printing technologies (FDM, SLA, SLS, etc.), where the material is heated and deposited layer by layer, forming the static structure of the object to be printed.

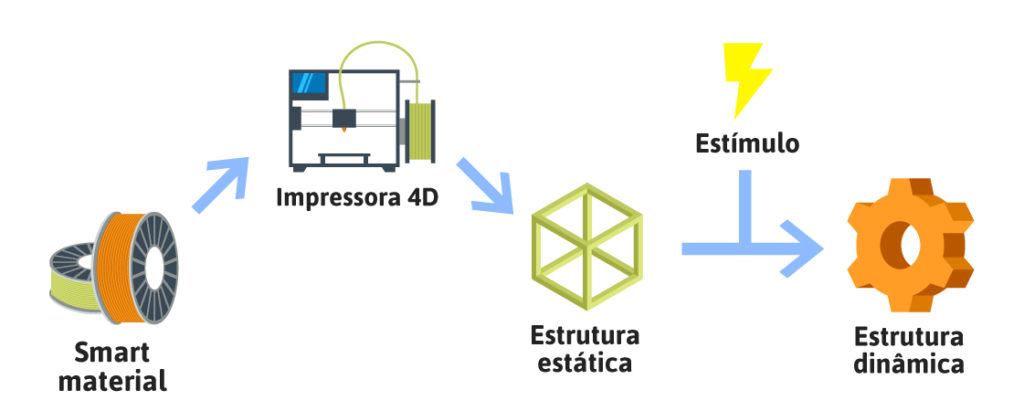

4D printing prints in the same way as 3D printing only using smart-materials, and in much the same way, an object with a static structure is generated. However, this structure becomes dynamic when there is any external stimulus such as temperature, light or water causing the object to change its shape.

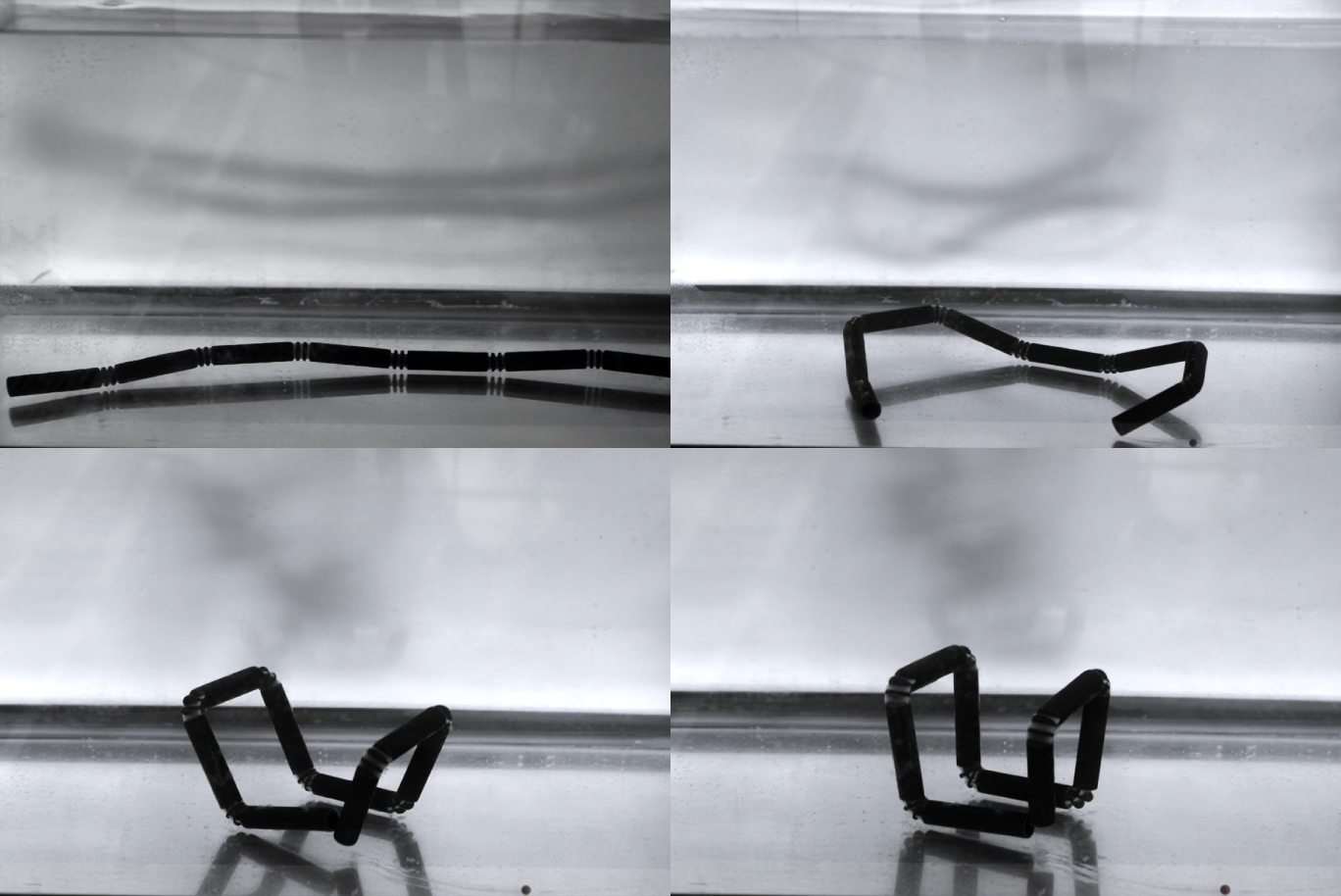

The images below show a tube that has been printed using a 4D printer (figure 1). It has been exposed to an environment that has a change in temperature and thus causes the object to “squirm” (figure 2 and 3). As you can see, it changes its shape until it reaches a shape with the desired angles ( figure 4).

Source: Above: Cube Self-folding Strand/Image Credit: Stratasys

What about applicability of 4D printing? Well, let’s look at some examples:

Hydraulic piping systems: one could print pipes capable of self-repair or pipes that increase or decrease their diameter according to the flow;

The transportable furniture industry: with 4D printing, it would be possible to print a flat plate that could be rolled up for transportation and then, when needed, it could change its shape to create the desired piece of furniture;

The fashion industry: clothing capable of changing its characteristics according to the weather. Another example could be, sneakers that change their size to fit the user’s foot;

The medical industry: development of shape-shifting proteins in the human body. Also, as we mentioned before, stents could be created that will lead to a less invasive surgery.

3D printing has proven that it can indeed be used in every field, and as 4D printing becomes a more concrete concept, it is certain to open new doors to advancements in many existing technologies.

Chances are, in the not too distant future, you will come across 4D-printed objects without even knowing it. Perhaps with an implant that adjusts to an aging body, or a new pair of sneakers that become waterproof in the rain and then more breathable when they get hot. The new revolution.